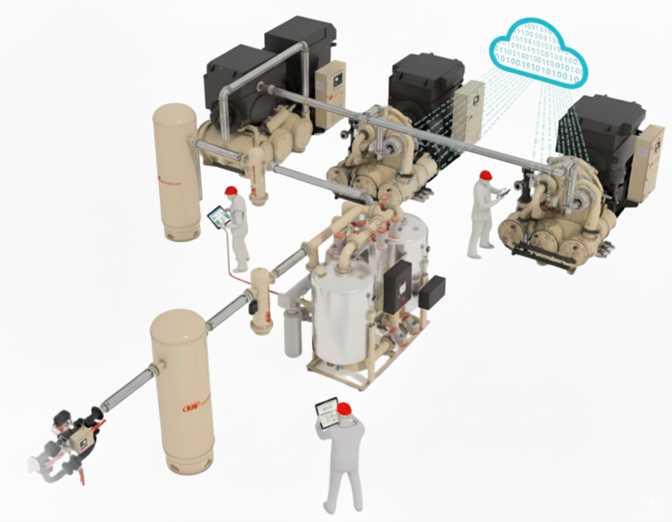

Machine Health Check- Up & Condition Monitoring.

Rotary & Turbo Compressors Performance Assessment Services

- Clearer understanding of system performance

- Reduce operating expenses

- Optimize Energy

- Prepare for future expansion

Gulf Riyadah Performance Services provides the insights necessary to fully optimize your system.

By identifying, analysing and resolving issues across the entire compressed air network, our teams apply data-driven analysis to uncover the root causes of operational challenges. Based on these findings, we recommend practical and cost-effective solutions designed to enhance profitability and minimize total cost of ownership.

Through data-driven approach, we deliver a customized plan tailored to your facility’s requirements helping you to:

- Address existing inefficiencies within your system

- Enhance energy efficiency and reduce environmental impact

- Detect and prevent potential issues before they escalate

- Gain comprehensive insights that support improved return on investment (ROI)

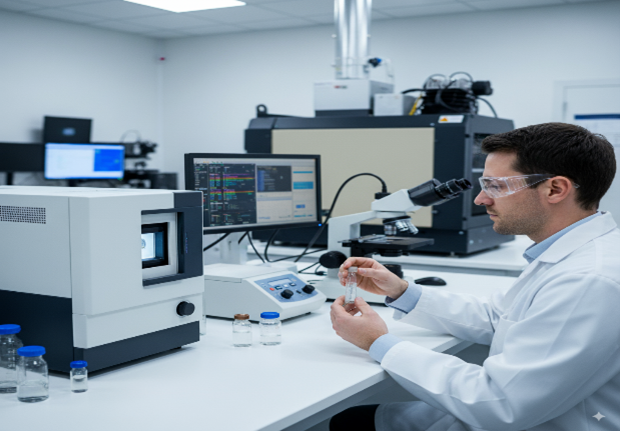

Machine Health Check- Up

Air Compressor Health Check-up & Condition monitoring are preventive maintenance services that evaluates the performance, efficiency, and reliability of your compressed air system. The process involves a comprehensive inspection of key components including filters, belts, lubricants, motors, energy along with diagnostic measurements such as pressure, temperature and vibration.

It is a proactive approach to maintain air compressors by assessing their operating health and performance with built-in or additional instruments. Instead of waiting for faults to occur, this method tracks the condition of critical components and identifies early signs of potential failure.

Gulf Riyadah offers you comprehensive package for compressed air systems assessments (audits) & machine health analysis services on all type of air compressors. This service provides clear insights through customized reports, enabling you to make informed decisions that maximize reliability, efficiency, and return on investment.

Shock Pulse Monitoring (SPM) is a specialized technique used to evaluate the condition of rotating parts in air compressors. SPM sensors measure shock pulses generated by friction or impacts inside the bearing. This allows early prediction detection of bearing wear. By identifying problems at an early stage can help to plan overhauling well breakdown & waiting for replacement.

By analysing data, our experts can predict problems before they lead to unexpected breakdowns. This not only reduces downtime but also helps in planning maintenance activities more effectively.

Benefits of Condition Monitoring:

- Improved reliability and longer equipment life

- Lower maintenance and repair costs

- Reduced energy losses and operating expenses

- Enhanced safety and productivity